Polymers are large molecules made from repeating structural units connected by covalent chemical bonds. We often use the word ‘plastic’ to refer to polymeric materials, but polymers also include a wide range of natural materials such as proteins, DNA, cellulose, shellac and amber.

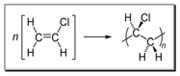

One example of a commonly synthesized polymer is polyvinyl chloride (PVC), which is used for plumbed piping, building materials, vinyl siding, and many other products with ‘vinyl’ in the name. PVC is made by polymerization of the vinyl chloride monomer as shown below.

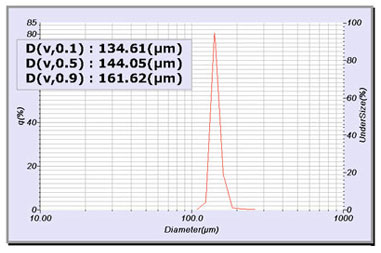

PVC is available in many size ranges, including large flakes. The data shown below was generated on the CAMSIZER dynamic image analysis system.

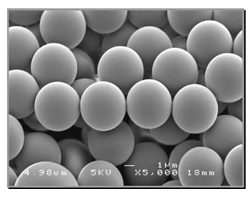

- 5 Micron Microspheres (photo courtesy of Duke Scientific)

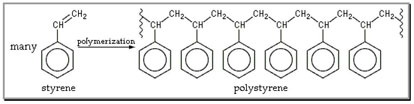

One polymer that many particle size analysts should be familiar with is polystyrene, the material often used for particle size standards. These standards are available in sizes ranging from 20 nm to 1000 μm. The particle size distribution for these samples is extremely narrow, therefore classifying them as monodisperse standards. Although most polystyrene samples are suspensions, powder materials are also available – see the example result below for a dry sample measured on theLA-950 laser diffraction analyzer.

- Polystyrene Latex Powder Result from the LA-950 with PowderJet Dry Feeder

Expanded polystyrene (EPS) can be found in many areas of our daily lives due to unique properties such as low thermal conductivity. Uses for this material range from practical applications (thermal insulation and noise dampening in building construction, and the manufacture of packaging for foodstuffs) to fun, niche markets (surfboard construction). The particle size range of EPS spheres covers 0.1 to approximately 3 millimeters.

The CAMSIZER is replacing the older, traditional technique of sieve analysis for EPS due to faster analysis speed and the valuable particle shape information provided by Dynamic Image Analysis. The result below shows excellent correlation between the CAMSIZER and historic sieve results for a sample of EPS.

Download the Application Note on Production Control of Polystyrene Beads using Digital Image Analysis (You need to be logged in).